ACOEM

Achieve precision with the Acoem AT-400 high-end dual-axis shaft alignment system.

Its Dual Sweep method captures accurate measurements during shaft rotation, ensuring optimal alignment. Benefit from Dual Multipoint for diverse scenarios, capturing multiple points for precise calculations. Cloud connectivity streamlines report sharing, while the lifetime warranty underscores its reliability.

Trust the Acoem AT-400 for robust dual-axis sensors and unparalleled versatility. Explore various measurement programs for horizontal, vertical, flatness, and soft foot conditions.

Highlights

Dual Measurement

Easily obtain readings with a single rotation of the shaft with Dual Sweep. With Dual Multipoint, record measu- rements in a tight space and from multiple points from any position on the rotation. Witness real-time visualization in both horizontal and vertical directions simultaneously with Dual View throughout the entire alignment.

Cloud Connectivity

Supplied with cloud connectivity, the AT-400 allows users to effortlessly upload alignment reports to

Acoem’s proprietary web portal, ensuring seamless data management and easy access to alignment

records for analysis and comparison. With just a tap of a button, technicians can send their alignment reports directly to the portal, streamlining their process of

documentation.

Lifetime Warranty Benefit

The AT-400 comes with the added assurance of a lifetime warranty, providing customers with

unmatched peace of mind and long-term reliability. This commitment to quality reflects Acoem’s confidence in the durability and performance of this cutting-edge alignment system.

GuideU Interface

GuideU is the next generation of 3D shaft alignment graphical user interface – our patented, customizable, icon-driven and color-coded display system that makes measuring, aligning, and reporting simple. Featuring realistic machine graphics and animated help screens, the risk of human error is minimized to take the guesswork out of shaft alignment.

Measurement Methods

Dual Sweep Method

The Dual Sweep method automates the measurement recording during a sweep of the shafts, providing a convenient way to assess alignment on coupled machines. By recording numerous points, a precise result is ensured. The recording of data is stopped manually by the user.

Dual Sweep Express Method

This measurement method is similar to the classic Dual Sweep method, however, data recording halts automatically when shaft rotation ceases.

Dual Multipoint Method

The Dual Multipoint method enables measurement initiation from any position on the rotation, allowing recording of multiple points for optimized calculations. Ideal for uncoupled shafts, non-rotatable

shafts, sleeve bearings or journal bearings.

Dual Multipoint Express Method

Similar to the classic Multipoint method,this method records automated measurements for greater convenience.

Tripoint Method

In the Tripoint method, the alignment condition can be calculated by recording three points while rotating the shaft at least 60°. In this method, all points are recorded manually by the user.

Tripoint Express Method

This method seamlessly incorporates the Tripoint approach, offering the added advantage of fully automated measurements throughout the process.

Clock Method

Calculations are made by taking three points with 180° of rotation, great for when

machines are resting on non-horizontal foundations or when shafts are not coupled. It is useful for comparing measurement results with dial gauges and reverse rim methods.

Features

SIMULTANEOUS HORIZONTAL AND VERTICAL MEASUREMENTS

Acoem M9 & S9 sensors excel in measuring both dimensions concurrently, offering comprehensive insights.

HIGH RESOLUTION

Achieve unmatched precision with a 0.001mm resolution, capturing even the smallest variations for analysis

THINNESS AND LIGHTNESS

The thinnest 2-axis sensors at 305g, ensuring easy integration and mobility.

GENEROUS MEASUREMENT RANGE

Acoem M9 & S9 sensors cover up to 20 meters (65 ft) without compromising accuracy.

THOUGHTFUL DESIGN

Equipped with sliding covers, our sensors ensure product longevity and protection during storage.

LARGE DETECTOR EXCELLENCE

A substantial 20x20 mm² size and 0.001mm high-resolution capability make this detector ideal for demanding measurement tasks.

Horizontal Shaft Alignment& HSA 2-axis

Determine and correct the relative position of two horizontally mounted machines that are connected, so that the rotational centers of the shafts are collinear

Vertical Shaft Alignment

Determine and correct the relative position of two vertically/flange mounted machines that are connected, so that the rotational centers of the shafts are collinear.

Flatness

Using the Acoem T21 when paired with the M9 sensor, the deviation in distance between the laser plane and the measurement object can be measured in one or more positions.

SoftCheck™

Check if there is a soft foot condition to verify if the motor is not resting firmly on all its feet.

Target Values

Once you have determined the machine’s thermal expansion, this program will allow you to pre-set target values prior to starting your alignment work.

Spacer Shaft Alignment

For machines driven by spacer shafts (or membrane couplings), this specialized program will guide the user through the alignment process.

Sensor Specifications

Hardware Type

M9 1-1216, S9 1-1217

Physical

Housing Material

Anodized Aluminum frame and high impact ABS plastic.

Weight

M9: 306 g (10,8 oz) S9: 306 g (10,8 oz)

Dimensions

TD9: 100mm x 77,3mm x 43mm (3,9 in x 3,0 in x 1,7 in)

Environment

Operating Temp

-10 to 50 °C (14 to 122 °F)

Storage Temp

-20 to 70 °C (-4 to 158 °F)

Long term storage Temp Room Temp

18 to 28 °C (64 to 82 °F)

Battery Charging Temp

0 to 40 °C (32 to 104 °F

Relative humidity

10 – 90 %

Environmental protection

IP65 (Dust tight and protected against watere jets)

Sensing Technology

Laser

650 nm class II diode laser

Laser power

< 1 mW

Measurement distance

63 mm to 20 m

Detector

2-axis PSD

Detector sizeword

20 mm x 20 mm (0,79 in x 0,79 in)

Detector resolution

1 µm

Measurement accuracy

1% ± 3 µm

Signal processing

Digital signal processing with sidespot rejection, edge detection, ambient light

elimination and anti-vibration mode

Ambient light protection

Optical filtering and ambient light signal rejection.

Inclinometer

Dual High Performance MEMS inclinometers

Inclinometer

resolution 0,01°

Inclinometer accuracy

±0,1°

Gyroscope

6-Axis MEMS Inertial Motion Sensor with drift compensation and automatic field

calibration

Gyroscope accuracy

±1°

Battery

Type

High performance Li Ion rechargeable battery or external power

Operating time

8 hours continuous use (measuring)

Charging

8 h

LED indicators

Unit state, laser transmission and 5 battery status indicators with instant battery check

Communication

Wireless communication

Bluetooth low energy (Bluetooth 5)

Communication range

10 m (33 ft)

Connectors

1 USB Mini port (IP67)

ACOEM Alignment Display

A sunlight-readable, 8-inch capacitive multi-touch display with super-hardened Gorilla Glass, plus rain and glove mode.

IP67 ruggedness rating (including the ports) for fullywaterproof and dust-tight performance.

Wide operating temperatures of -20°C to 60°C (-4°F to 140°F).

Contains :

2 pcs of digital alignment sensors

2 pcs of V-brackets complete with chain

Extension fixture, 49 mm

Magnetic base

Thin magnetic fixtures

Rod kit

2 pcs of chains, 8 mm, 60 links (L=970 mm)

Tape measure, 5 m

2 pcs of angled universal tools

External power cable, EU, 2 m

External power cable, US, 2 m

2 pcs of USB-cables, A-mini B, 2 m

Power supply 5 USB-ports 5 VDC

Tablet

Also you can check product : NEW Acoem Falcon Ultimate Data Collector Vibration Analyzers

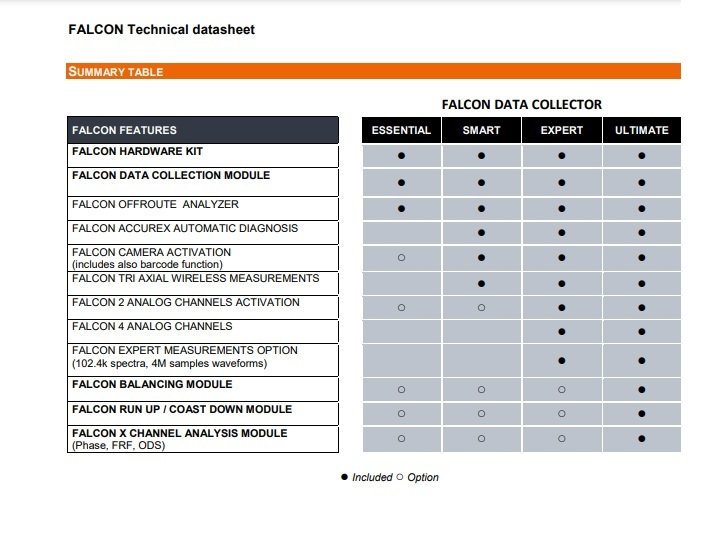

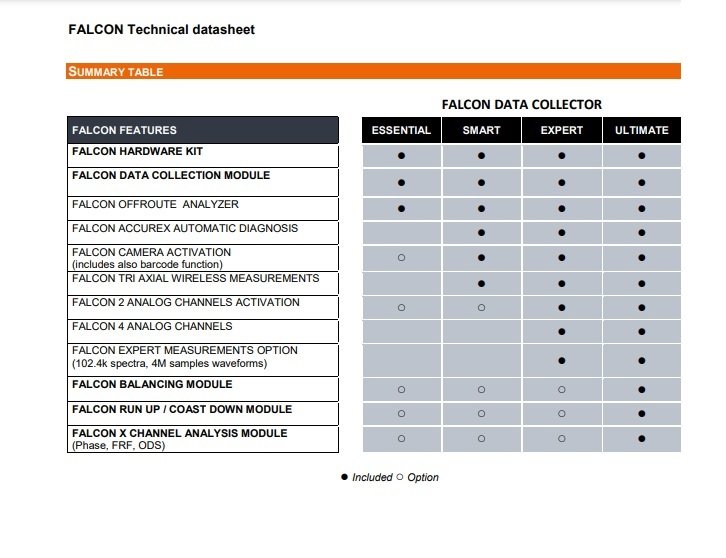

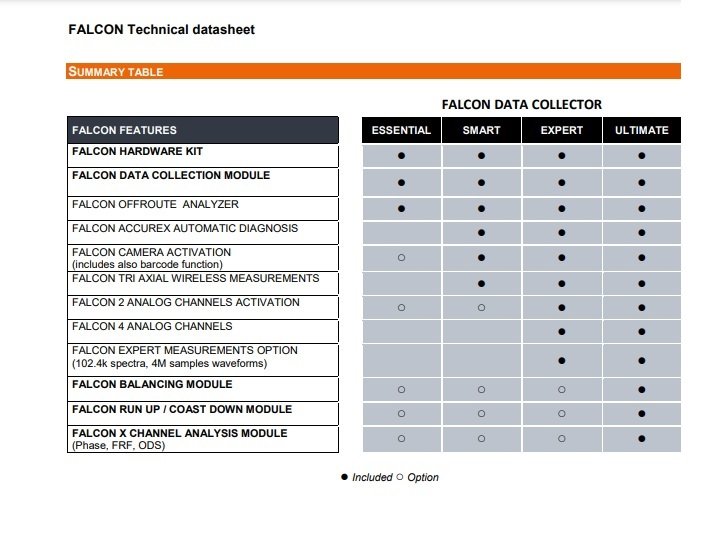

ACOEM ONEPROD Falcon Ultimate Data Collector Vibration Analyzers

Four-Channel Vibration Analyser, Collector, Balancer, Recorder

Main features:

Compact and light case

Single-hand operating (left or right)

Color screen/touch screen

Icon-based intuitive user interface

Online help

Wireless 3-axis sensor

Integrated stroboscope, contactless laser-sighting temperature sensors, no connection of external accessory required.

Automatic identification process of the measurement point by contactless reading of QR-code, preventing sensor positioning errors and reducing measurement time.

Operating comfort and safety are ensured even in the most severe

environments. OneproD Falcon is also suitable for extreme conditions encountered in chemical and petrochemical industry, iron and steel industry, paper industry, cement works, etc.:

IP65 protected

Shock-proof

Intrinsically safe version available (OneproD MVP-2EX)

Based on the latest technology, OneproD Falcon offers added performances, in a more and more compact form:

4 vibration channels 1 trigger input

Frequency range: up to 80 kHz

Resolution: 101 000 lines

Communication via USB, WiFi, Ethernet, Internet

Long-time recording, up to 80 seconds at 51.2 kHz, 4 Msamples

Memory: 4 GB

Automatic configuration

Automatic diagnosis

Multiple functions range from the mere control of vibration levels to the most sophisticated diagnoses:

Data collector MAC (Machine Auto Controller) witch cloud storage, Basic Route or Smart Route

2, 4 plane balancer

Four-channel analyser, future option

Digital recorder, future option

Order analysis, future option

Analyser module with CPB measurement: octave, 1/3rd octave and 1/12th octave, future option

Balancer module:

1 -4 plane balancing

Integrated sensors

OneproD Falcon includes two laser-sighting contactless sensors that allow, without any additional accessories, to complement data collections with temperature (pyrometry) and rotation speed (LED stroboscope) measurements. Since they usually require handling external accessories, these additional measurements are often neglected although they provide a better knowledge of the machines.

Note: Class 2 laser instrument, wavelength: 630-680 nm, max. power: 1 mW according to Standard NF EN 60825-1.

QR-code

Measurement point identification: each bearing (or machine) is equipped with an QR-code and remotely issues its code.You just need to bring OneproD Falcon a few centimetres away from the bearing and press the reading key using the camera. After reading this code, OneproD Falcon automatically sets up the corresponding measurement point and is ready to start data acquisition. This method ensures reliable and faster measurements (no more inversion of the measurement point).

Data Collector

OneproD Falcon is a performing tool to collect data associated with OneproD XPR-300 Predictive Maintenance Software. Three levels of functions are available to meet closely your requirement at the most competitive price.

With its integrated sensors (laser-sighting pyrometer and LED stroboscope, automatic identification of the measurement point), only one cable (that of the vibration transducer) or wireless transducer is required to identify the measurement point and measure the data that are characteristic of the operating state of your machines (vibration, rotation speed, temperature):

Compactness

Speediness

Four channel measurement: faster, orbit analysis

Flash acquisition to speed up data collection

Single-hand measurements (left or right)

Shock-proof, IP65 protection

Organisation of measurements in a 4-level tree system

Automatic sequencing of measurements performed at the same geographic spot

Inspection notes

?Review? function to analyse measurement data directly on the instrument

Off-route measurements: – the level tree structure – copy and paste of machine, point or measurement

Balancer

This optional module is used to correct balancing defects on simple and complex machines.

From 1 to 4 balancing planes

Polar display of measurements

Storage of more than 1000 balancings

One-run balancing capability

Information on the measurement deviation (rotation speed, vibration)

Polar display of trial and correction weights

Splitting of correction weights

Display of balancing quality

Using two-channel/four-channel option, parallel measurements on 2/4 sensors are possible, resulting in a faster, safer and more accurate procedure

Analyser, future option

With this version, measurements and diagnoses can be performed directly on the instrument: overall level control, time and spectrum analysis. The two-channel option offers numerous other functions, such as orbit analysis for journal bearing machines and transfer function for the characterisation of mechanical resonances. Measurement data may be processed on a PC using the vib-Graph software.

Measurement organisation based on a 3-level tree structure Fast generation – using copy/paste functions at all levels.

Functions :

Instantaneous time spectrum

Power autospectrum

RMS spectrum

Cross-spectrum

Transfer function

Transmissibility

Coherence

Display

1, 2, 3, 4 traces

Linear or logarithmic amplitude, phase, real part, imaginary part

Orbit

Shock acquisition

Windowing

Averaging with validation

SPECS :

Touchscreen

Graphic colour touchscreen

Resolution: 800x480 pixels

Dimension: 154x92 mm (D7”)

Adjustable brightness

Can be used in direct sunlight

Icon functions

Touch keyboard

On touchscreen:

- 10 contextual function keys

- Functions are organised for single-hand measurement (left or right)

- Direct access to general functions: Home, Help, Setup, Screen copy, Picture, Bar code reader, Text note, Audio comment,Pyrometer, Stroboscope

- Full keyboard for text input. Several keyboards available: qwerty, azerty, Cyrillic,

Chinese

Acquisition

Synchronous on 4 channels trigger input 4-bits conversion

Sampling frequency:

- 102.4 kHz for each channel

- Up to 204.8 kHz on 1 channel

Antialiasing filter

Wireless acquisition with FALCON WLS triaxial

accelerometer

Digital signal processors

Real-time processing:

- 40 kHz on 4 channels

- Up to 80 kHz on 2 channels

Memory: 3.5 GB for measurements

Communication

USB 2 type B device (direct connection to PC)

USB 2 type A host (for USB stick)

Ethernet

Wi-Fi

Battery

Auto test and calibration function

High density Li-Ion type

Rechargeable without removing

Battery lifetime: 10 hours under intense use

Programmable automatic standby mode and switch-off

Analogue Inputs

Up to 4 programmable signal inputs (depending on instrument option):

- Frequency range: 0 - 40 kHz on 4 channels, 80 kHz on 1 channel

- Overload indicator in % with memorisation

- IEPE interface with real time integrity control, range 8V (power supply: 4 mA constant

current 23 VDC)

- Dynamic signal measurements (acceleration, vibration velocity, absolute displacement, relative displacement, electrical current, etc.)

- /- 10 VAC

- 0, -24 V for proximity probes (a -

24Vdc power supply is available

on each channel using cable ref

FLC1005000))

- Input impedance AC/DC: 100 kΩ

- Accuracy: /- 1%

- Dynamic range > 90dB

- Sensors without electronics with optional charge amplifier

- DC input: from -24 VDC to 24 VDC for measurements of position and process parameters

- AC coupling: 0.3 Hz

- Compatible with triaxial senso

Trigger input:

Range: /- 10 V, 0 to 24 V, 0 to – 24 V

Adjustable triggering parameters

Automatic setup function

For rotation speed measurement, synchronous analysis, balancing, order analysis.

Input impedance: 100 kΩ

5 Vdc power supply for tacho probe

-24 Vdc power supply for proximity probes driver using optional cable ref FLC1006000

Microphone input

Microphone input for audio inspection notes

ANALOGUE OUTPUTS

1 headphone output to listen sensor signal, recorded

signal or audio inspection notes

1 stroboscope output: TTL For each channel and trigger input:

-24 Vdc power supply for proximity probe

BUILT-IN PYROMETER WITH LASER-SIGHTING

Contactless temperature measurement:

- Range: 0 to 200°C

- Accuracy: /- 3°C for ambient temperature

ranging from 18°C to 28°C.

- Resolution: 0.5°C

- Repeatability: /- 1°C

- Field of view: 5° @ 50% ( target ≃ 4 cm @ 50 cm)

- Time response: 1 s

- Fixed emissivity: 95%

BUILT-IN STROBOSCOPE

Rotation speed measurement:

- Range: 30 to 15000 RPM

- Automatic setting to machine speed predefined in setup

- Adjustment:

-½, x2

-Fast

-Fine

- Flash duration : adjustable from 0.5 to 15°

- Can be used independently or to adjust rotation speed in a route or from a spectrumdisplay

Built-in camera

Resolution: 640 x 480

Autofocus

Distance: 20 cm to - Flash mode

Identification of measurement point

Built-in bar code reader

Reading distance: from 20 cm to 50 cm according to

code dimension

Bar code format: QRcode

Learning mode to avoid codes manual input

Mechanical/environment

Protection: IP65.

Case with shock protection rubber

Shock protection: 1.2 m drop (1m for EX version)

Standard compliance:

-Safety: IEC61010-1

-EMC: directive 2004-108-CE

Dimensions: 200 x 265 x 65 mm

Weight: 1.8 kg including battery and rubber protection

Operating temperature: -10°C to 55°C

Humidity: 95% no condensation

FALCON-EX, intrinsically safe version:

ATEX certification: EX II 3 G, Ex ic IIC T4 Gc, supplied

with certified accessories.

IECEX certification: Ex ic IIC T4 Gc

Note: shock protection: 1m drop. The protection screenaccessory cannot be used in dangerous area and is not supplied.

Remote access

FALCON can be set up so as to communicate with your network through its Ethernet or Wi-Fi interface and used as a remote station. You can then use the applications installed on your computer directly from FALCON (SUPERVISION, CMMS…)

Also you can check product : NEW Acoem Falcon Expert Data Collector Vibration Analyzers

The AT-300’s seamless integration of connectivity, mobile devices, and apps empowers maintenance professionals to swiftly respond to machine failures and take corrective actions regardless of their location.

Utilizing the newest and latest CCD technology, the smart sensors deliver superior measurement performance, ensuring precise alignment and optimal operational efficiency. This advanced tool streamlines maintenance processes, minimizing downtime and maximizing productivity.

Smart Alignment Sensors

Large 30mm digital sensor detectors

Long measuring distance (up to 49 Feet)

Thinnest sensors on the market (34mm)

IP65 Certified to withstand harsh environments

Integrated Bluetooth® for wireless communication to display unit

Built-In dual inclinometers for backlash and angular values

Multiple Measurement Methods

With the AT-300, you can measure misalignment with five different measurement methods. Each method includes benefits for different types of machinery.

Interface Features

The AT-300 interface is designed to make the user experience hassle-free as well as maximize user productivity, facilitate intuitive reporting, and ensure a consistent user experience across all measurements.

GuideU Interface

GuideU is the next generation of 3D shaft alignment graphical user interface – our patented, customizable, icon-driven and color-coded display system that makes measuring, aligning, and reporting simple. Featuring realistic machine graphics and animated help screens, the risk of human error is minimized to take the guesswork out of shaft alignment.

Cloud Connectivity

Supplied with cloud connectivity, the AT-300 allows users to effortlessly upload alignment reports to Acoem’s proprietary web portal, ensuring seamless data management and easy access to alignment records for analysis and comparison. With just a tap of a button, technicians can send their alignment reports directly to the portal, streamlining their process of documentation.

AT-300 Technical Datasheet

M10 & S10 Sensors

Hardware Type

M10 1-1216, S10 1-1217

Physical

Housing Material

Anodized Aluminum frame and high impact ABS plastic overmolded with TPE rubber.

Weight

M10: 7.5 oz (212 g)

S10: 6.6 oz (188 g)

Dimensions

M10: 3.6 in x 3.0 in x 1.3 in (92mm x 77mm x 33mm)

S10: 3.5 in x 3.0 in x 1.3 in (88mm x 77mm x 33mm)

Environment

Operating Temperature

14 to 122 °F (-10 to 50 °C)

Storage Temperature

-4 to 158 °F (-20 to 70 °C)

Long Term Storage Room Temperature

64 to 82 °F (18 to 28 °C)

Battery Charging Temperature

32 to 104 °F (0 to 40 °C)

Relative Humidity

10 – 90 %

Environmental Protection

IP65 (Dust tight and protected against water jets)

Sensing Technology

Laser

650 nm class II diode laser

Laser Power

< 1 mW

Measurement Distance

Up to 49 ft (15m)

Detector

3rd Gen. Digital Sensor

Detector Angular Subtense

30mrad/m (3mm/100mm per meter)

Detector Resolution

1 μm

Measurement Accuracy

0.3% ± 7 μm

Signal Processing

Digital signal processing with sidespot rejection, edge detection, ambient light elimination and anti-vibration mode.

Ambient Light Protection

Optical filtering and ambient light signal rejection

Inclinometer

Dual High Performance MEMS inclinometers

Inclinometer Resolution

0.01 °

Inclinometer Accuracy

±0.2 °

Gyroscope

6-Axis MEMS Inertial Motion Sensor w/ Drift Compensation and Automatic Field Calibration

Gyroscope Accuracy

±1 °

Battery

Type

High Performance Li-ion Rechargeable Battery or External Power

Operating Time

20 Hours Continuous Use (Measuring)

Charging

8 Hours

LED Indicators

Unit State, Laser Transmission and 5 Battery Status Indicators with Instant Battery Check

Communication

Wireless Communication

Bluetooth Low Energy (Bluetooth 5)

Communication Range

33 ft (10m)

Connectors

1 USB Mini Port (IP67)

Acoem Alignment Display Unit

Display

Sunlight Readable, Capacitive Multi-Touch Display, Super-Hardened Gorilla Glass, Rain and Glove Mode

Display Size

8 in

Ruggedness Rating

IP67 (Including Ports), Waterproof and Dust-Tight

Operating Temperature

-4°F to 140°F (-20°C to 60°C)

INCLUDED :

Acoem AT Display Unit

Acoem S10 Alignment Sensor

Acoem M10 Alignment Sensor

V-Bracket Complete x2

Quick Guide AT

USB-Cable A-Mini B 2m (6.5 ft)

Chain 8mm (0.3 in) 60 Links

(L=970mm (38.2 in))

Power Supply 4 USB-Ports 5 VDC

Magnetic V-Brackets x2

Extension Fixture 49mm (1.93 in)

Magnetic Base On-Off

Tape Measure (16.5 in)

Acoem USB

Angled Universal Tool x2

Rod Kit

Also you can check product : NEW Acoem AT-400 D Laser Shaft Alignment Tool

ACOEM ONEPROD Falcon Smart Data Collector Vibration Analyzers

Four-Channel Vibration Analyser, Collector, Balancer, Recorder

Main features:

Compact and light case

Single-hand operating (left or right)

Color screen/touch screen

Icon-based intuitive user interface

Online help

Wireless 3-axis sensor

Integrated stroboscope, contactless laser-sighting temperature sensors, no connection of external accessory required.

Automatic identification process of the measurement point by contactless reading of QR-code, preventing sensor positioning errors and reducing measurement time.

Operating comfort and safety are ensured even in the most severe

environments. OneproD Falcon is also suitable for extreme conditions encountered in chemical and petrochemical industry, iron and steel industry, paper industry, cement works, etc.:

IP65 protected

Shock-proof

Intrinsically safe version available (OneproD MVP-2EX)

Based on the latest technology, OneproD Falcon offers added performances, in a more and more compact form:

4 vibration channels 1 trigger input

Frequency range: up to 80 kHz

Resolution: 101 000 lines

Communication via USB, WiFi, Ethernet, Internet

Long-time recording, up to 80 seconds at 51.2 kHz, 4 Msamples

Memory: 4 GB

Automatic configuration

Automatic diagnosis

Multiple functions range from the mere control of vibration levels to the most sophisticated diagnoses:

Data collector MAC (Machine Auto Controller) witch cloud storage, Basic Route or Smart Route

2, 4 plane balancer

Four-channel analyser, future option

Digital recorder, future option

Order analysis, future option

Analyser module with CPB measurement: octave, 1/3rd octave and 1/12th octave, future option

Balancer module:

1 -4 plane balancing

Integrated sensors

OneproD Falcon includes two laser-sighting contactless sensors that allow, without any additional accessories, to complement data collections with temperature (pyrometry) and rotation speed (LED stroboscope) measurements. Since they usually require handling external accessories, these additional measurements are often neglected although they provide a better knowledge of the machines.

Note: Class 2 laser instrument, wavelength: 630-680 nm, max. power: 1 mW according to Standard NF EN 60825-1.

QR-code

Measurement point identification: each bearing (or machine) is equipped with an QR-code and remotely issues its code.You just need to bring OneproD Falcon a few centimetres away from the bearing and press the reading key using the camera. After reading this code, OneproD Falcon automatically sets up the corresponding measurement point and is ready to start data acquisition. This method ensures reliable and faster measurements (no more inversion of the measurement point).

Data Collector

OneproD Falcon is a performing tool to collect data associated with OneproD XPR-300 Predictive Maintenance Software. Three levels of functions are available to meet closely your requirement at the most competitive price.

With its integrated sensors (laser-sighting pyrometer and LED stroboscope, automatic identification of the measurement point), only one cable (that of the vibration transducer) or wireless transducer is required to identify the measurement point and measure the data that are characteristic of the operating state of your machines (vibration, rotation speed, temperature):

Compactness

Speediness

Four channel measurement: faster, orbit analysis

Flash acquisition to speed up data collection

Single-hand measurements (left or right)

Shock-proof, IP65 protection

Organisation of measurements in a 4-level tree system

Automatic sequencing of measurements performed at the same geographic spot

Inspection notes

?Review? function to analyse measurement data directly on the instrument

Off-route measurements: – the level tree structure – copy and paste of machine, point or measurement

Balancer

This optional module is used to correct balancing defects on simple and complex machines.

From 1 to 4 balancing planes

Polar display of measurements

Storage of more than 1000 balancings

One-run balancing capability

Information on the measurement deviation (rotation speed, vibration)

Polar display of trial and correction weights

Splitting of correction weights

Display of balancing quality

Using two-channel/four-channel option, parallel measurements on 2/4 sensors are possible, resulting in a faster, safer and more accurate procedure

Analyser, future option

With this version, measurements and diagnoses can be performed directly on the instrument: overall level control, time and spectrum analysis. The two-channel option offers numerous other functions, such as orbit analysis for journal bearing machines and transfer function for the characterisation of mechanical resonances. Measurement data may be processed on a PC using the vib-Graph software.

Measurement organisation based on a 3-level tree structure Fast generation – using copy/paste functions at all levels.

Functions :

Instantaneous time spectrum

Power autospectrum

RMS spectrum

Cross-spectrum

Transfer function

Transmissibility

Coherence

Display

1, 2, 3, 4 traces

Linear or logarithmic amplitude, phase, real part, imaginary part

Orbit

Shock acquisition

Windowing

Averaging with validation

SPECS :

Touchscreen

Graphic colour touchscreen

Resolution: 800x480 pixels

Dimension: 154x92 mm (D7”)

Adjustable brightness

Can be used in direct sunlight

Icon functions

Touch keyboard

On touchscreen:

- 10 contextual function keys

- Functions are organised for single-hand measurement (left or right)

- Direct access to general functions: Home, Help, Setup, Screen copy, Picture, Bar code reader, Text note, Audio comment,Pyrometer, Stroboscope

- Full keyboard for text input. Several keyboards available: qwerty, azerty, Cyrillic,

Chinese

Acquisition

Synchronous on 4 channels trigger input 4-bits conversion

Sampling frequency:

- 102.4 kHz for each channel

- Up to 204.8 kHz on 1 channel

Antialiasing filter

Wireless acquisition with FALCON WLS triaxial

accelerometer

Digital signal processors

Real-time processing:

- 40 kHz on 4 channels

- Up to 80 kHz on 2 channels

Memory: 3.5 GB for measurements

Communication

USB 2 type B device (direct connection to PC)

USB 2 type A host (for USB stick)

Ethernet

Wi-Fi

Battery

Auto test and calibration function

High density Li-Ion type

Rechargeable without removing

Battery lifetime: 10 hours under intense use

Programmable automatic standby mode and switch-off

Analogue Inputs

Up to 4 programmable signal inputs (depending on instrument option):

- Frequency range: 0 - 40 kHz on 4 channels, 80 kHz on 1 channel

- Overload indicator in % with memorisation

- IEPE interface with real time integrity control, range 8V (power supply: 4 mA constant

current 23 VDC)

- Dynamic signal measurements (acceleration, vibration velocity, absolute displacement, relative displacement, electrical current, etc.)

- /- 10 VAC

- 0, -24 V for proximity probes (a -

24Vdc power supply is available

on each channel using cable ref

FLC1005000))

- Input impedance AC/DC: 100 kΩ

- Accuracy: /- 1%

- Dynamic range > 90dB

- Sensors without electronics with optional charge amplifier

- DC input: from -24 VDC to 24 VDC for measurements of position and process parameters

- AC coupling: 0.3 Hz

- Compatible with triaxial senso

Trigger input:

Range: /- 10 V, 0 to 24 V, 0 to – 24 V

Adjustable triggering parameters

Automatic setup function

For rotation speed measurement, synchronous analysis, balancing, order analysis.

Input impedance: 100 kΩ

5 Vdc power supply for tacho probe

-24 Vdc power supply for proximity probes driver using optional cable ref FLC1006000

Microphone input

Microphone input for audio inspection notes

ANALOGUE OUTPUTS

1 headphone output to listen sensor signal, recorded

signal or audio inspection notes

1 stroboscope output: TTL For each channel and trigger input:

-24 Vdc power supply for proximity probe

BUILT-IN PYROMETER WITH LASER-SIGHTING

Contactless temperature measurement:

- Range: 0 to 200°C

- Accuracy: /- 3°C for ambient temperature

ranging from 18°C to 28°C.

- Resolution: 0.5°C

- Repeatability: /- 1°C

- Field of view: 5° @ 50% ( target ≃ 4 cm @ 50 cm)

- Time response: 1 s

- Fixed emissivity: 95%

BUILT-IN STROBOSCOPE

Rotation speed measurement:

- Range: 30 to 15000 RPM

- Automatic setting to machine speed predefined in setup

- Adjustment:

-½, x2

-Fast

-Fine

- Flash duration : adjustable from 0.5 to 15°

- Can be used independently or to adjust rotation speed in a route or from a spectrumdisplay

Built-in camera

Resolution: 640 x 480

Autofocus

Distance: 20 cm to - Flash mode

Identification of measurement point

Built-in bar code reader

Reading distance: from 20 cm to 50 cm according to

code dimension

Bar code format: QRcode

Learning mode to avoid codes manual input

Mechanical/environment

Protection: IP65.

Case with shock protection rubber

Shock protection: 1.2 m drop (1m for EX version)

Standard compliance:

-Safety: IEC61010-1

-EMC: directive 2004-108-CE

Dimensions: 200 x 265 x 65 mm

Weight: 1.8 kg including battery and rubber protection

Operating temperature: -10°C to 55°C

Humidity: 95% no condensation

FALCON-EX, intrinsically safe version:

ATEX certification: EX II 3 G, Ex ic IIC T4 Gc, supplied

with certified accessories.

IECEX certification: Ex ic IIC T4 Gc

Note: shock protection: 1m drop. The protection screenaccessory cannot be used in dangerous area and is not supplied.

Remote access

FALCON can be set up so as to communicate with your network through its Ethernet or Wi-Fi interface and used as a remote station. You can then use the applications installed on your computer directly from FALCON (SUPERVISION, CMMS…).

Also you can check product : NEW Acoem Falcon Ultimate Data Collector Vibration Analyzers

Connected insights empowering your plant and teams!

On-the-spot machine diagnostics with a complete precision shaft alignment tool and a cloud connection to save reports and look up historical data, all combined into one tool — the RT-300 is a truly unique reliability tool for the Industry 4.0 mechanic!

Powered by the suite of intuitive applications offered by Acoem, this tool does it all: shaft alignment, vibration analysis, spot inspections on bearings, and safe and reliable measurement with the unique probe for of all pre-alignment checks.

A complete precision shaft alignment tool, on-the-spot machine diagnostics, and a cloud connection for storing reports and reviewing historical data, all combined into one tool, the RT-300 is a unique tool for Industry 4.0 mechanics.

Shaft Alignment

IP65 certified sensor design that can withstand harsh environments

30 mm digital sensor detector line laser eliminate rough alignment and give you ashort setup time

Premounted fixtures and small sensors provide quick setup also on machines with limited space

True Live

No doubts, no guessing games, thanks to the industry-first use of technologies of two smart sensors with visible laser beams and inclinometers monitoring both shaft positions simultaneously.

Did you interrupt the laser beam? Or move the machine’s position out of the detector range? Not a problem, our smart sensors will resume with an updated machine position and always deliver live values to you.

Pre-Alignment

The Run-Out probe - a smart displacement probe for safe and reliable measurement of axial and radial runout

High Precision & Wireless probe that measures directly on the machine foot.

LVDT sensor with ± 2,5 mm measurement range and high precision (within 0.005 mm).

The Runout probe performs a multitude of applications that will improve your machines’ health and lifetime, eg:

Axial and radial runout checks on flanges and shafts through measuring eccentric or skewed mounting of coupling hubs, and/or checking for bent shafts - Run-Out

Checking movements directly on machine feet, ie soft foot – True SoftCheck, an industry-first function

Checking bearing clearances - LiftCheck

Checking movements due to pipe strain

Thermal growth measurements on machine casings

RT-300 Features

A CENTRALIZED SYSTEM

Accurex AI for automatic diagnosis and cloud-connected

WIRELESS SENSOR

Tri-axial and piezoelectric sensor with simultaneous triaxial vibration temperature

THOUGHTFULLY DESIGNED

Rugged tablet-based system pre-loaded with 5 unique applications

CAPABILITIES

Vibration and alignment in one

RUNOUT PROBE AND STAND

Linear variable displacement transducer (LVDT)with a three-joint articulated arm

Technical Data :

S7/ M7

Housing Material

Anodized Aluminum frame and high impact ABS plastic overmolded with TPE rubber

Operating Temp:

-10 to 50°C (14 to 122°F)

Storage Temp:

-20 to 70°C ( -4 to 158°F)

Battery Charging Temp:

0 to 40°C ( 32 to 104°F)

Relative humidity:

10 – 90%

Weight:

M7: 212 g (7,5 oz) S7: 188 g (6,6 oz)

Dimensions:

92mm x 77mm x 33mm (3,6 in x 3,0 in x 1,3 in)

Environmental protection:

IP 65 (Dust tight and protected against water jets)

Laser:

650 nm class II diode laser

Laser line fan angle:

6°

Laser line divergence (full angle):

0.25 mrad

Laser power:

< 1 mW

Measurement distance:

Up to 10m

Detector:

2nd gen. digital sensor

Detector length:

30mm ( 1,2 in )

Detector resolution:

1 µm

Measurement accuracy:

0,3% ± 7 µm

Signal processing:

Digital signal processing with Sidespot rejection, edge detection, ambient light elimination and anti-vibration mode

Inclinometer:

Dual High Performance MEMS inclinometers

Inclinometer resolution:

0,01°

Inclinometer accuracy:

±0,2°

Wireless communication:

Class I Bluetooth transmitter

Communication range:

10 m (33 ft)

Charging:

5V, 0,5A

Power supply:

High performance Li Ion battery or external power.

Operating time:

17 hours continuous use (measuring)

Battery Charging time (system off, room temperature):

8 h

WLS

Three axial measurements:

Synchronous acquisition in X, Y and Z directions

Sampling frequency:

51.2 kHz on all axes (Fmax 20kHz)

Full bandwidth:

20 kHz on all axes

Accuracy:

/- 5% @ 120 Hz, 1g

Dimensions:

Ø42 x H116 mm

Weight:

373 g

Mounting:

M6 threaded hole

Housing material:

Stainless steel

Operating temperature range:

-20°C to 60°C

Resistance to shocks:

5,000 g peak

Protection:

IP65

Battery Type:

Li-Ion

Operating lifetime:

8 hours

Rechargeable:

By USB (power supply adapter in standard delivery)

Charging time:

~8 hours with the standard 500 mA charge current.

Wireless protocol:

Wi-Fi Point to point 2.4GHz

Wireless range:

Up to 25 meters line of sight depending on the environ- ment.

Included :

2 pcs of digital alignment sensors

2 pcs of V-brackets complete with chain

Runout probe

Sensor stand (without magnetic base)

Adjustable probe tip

Wireless sensor (WLS)

Magnetic base

Rod kit

2 pcs of chains, 8 mm, 60 links (L=970 mm)

Tape measure 5 m

2 pcs of angled universal tools

Ext power cable EUR 2 m

Extension fixture 49 mm

Ext power cable US 2m

USB-cable A-mini B 2m

USB-cable A-micro B 1,5m

Power supply 5 USB-ports 5 VDC

Also you can check product : NEW Acoem AT-300 D Laser Shaft Alignment Tool

ACOEM ONEPROD Falcon Expert Data Collector Vibration Analyzers

Four-Channel Vibration Analyser, Collector, Balancer, Recorder

Main features:

Compact and light case

Single-hand operating (left or right)

Color screen/touch screen

Icon-based intuitive user interface

Online help

Wireless 3-axis sensor

Integrated stroboscope, contactless laser-sighting temperature sensors, no connection of external accessory required.

Automatic identification process of the measurement point by contactless reading of QR-code, preventing sensor positioning errors and reducing measurement time.

Operating comfort and safety are ensured even in the most severe

environments. OneproD Falcon is also suitable for extreme conditions encountered in chemical and petrochemical industry, iron and steel industry, paper industry, cement works, etc.:

IP65 protected

Shock-proof

Intrinsically safe version available (OneproD MVP-2EX)

Based on the latest technology, OneproD Falcon offers added performances, in a more and more compact form:

4 vibration channels 1 trigger input

Frequency range: up to 80 kHz

Resolution: 101 000 lines

Communication via USB, WiFi, Ethernet, Internet

Long-time recording, up to 80 seconds at 51.2 kHz, 4 Msamples

Memory: 4 GB

Automatic configuration

Automatic diagnosis

Multiple functions range from the mere control of vibration levels to the most sophisticated diagnoses:

Data collector MAC (Machine Auto Controller) witch cloud storage, Basic Route or Smart Route

2, 4 plane balancer

Four-channel analyser, future option

Digital recorder, future option

Order analysis, future option

Analyser module with CPB measurement: octave, 1/3rd octave and 1/12th octave, future option

Balancer module:

1 -4 plane balancing

Integrated sensors

OneproD Falcon includes two laser-sighting contactless sensors that allow, without any additional accessories, to complement data collections with temperature (pyrometry) and rotation speed (LED stroboscope) measurements. Since they usually require handling external accessories, these additional measurements are often neglected although they provide a better knowledge of the machines.

Note: Class 2 laser instrument, wavelength: 630-680 nm, max. power: 1 mW according to Standard NF EN 60825-1.

QR-code

Measurement point identification: each bearing (or machine) is equipped with an QR-code and remotely issues its code.You just need to bring OneproD Falcon a few centimetres away from the bearing and press the reading key using the camera. After reading this code, OneproD Falcon automatically sets up the corresponding measurement point and is ready to start data acquisition. This method ensures reliable and faster measurements (no more inversion of the measurement point).

Data Collector

OneproD Falcon is a performing tool to collect data associated with OneproD XPR-300 Predictive Maintenance Software. Three levels of functions are available to meet closely your requirement at the most competitive price.

With its integrated sensors (laser-sighting pyrometer and LED stroboscope, automatic identification of the measurement point), only one cable (that of the vibration transducer) or wireless transducer is required to identify the measurement point and measure the data that are characteristic of the operating state of your machines (vibration, rotation speed, temperature):

Compactness

Speediness

Four channel measurement: faster, orbit analysis

Flash acquisition to speed up data collection

Single-hand measurements (left or right)

Shock-proof, IP65 protection

Organisation of measurements in a 4-level tree system

Automatic sequencing of measurements performed at the same geographic spot

Inspection notes

?Review? function to analyse measurement data directly on the instrument

Off-route measurements: – the level tree structure – copy and paste of machine, point or measurement

Balancer

This optional module is used to correct balancing defects on simple and complex machines.

From 1 to 4 balancing planes

Polar display of measurements

Storage of more than 1000 balancings

One-run balancing capability

Information on the measurement deviation (rotation speed, vibration)

Polar display of trial and correction weights

Splitting of correction weights

Display of balancing quality

Using two-channel/four-channel option, parallel measurements on 2/4 sensors are possible, resulting in a faster, safer and more accurate procedure

Analyser, future option

With this version, measurements and diagnoses can be performed directly on the instrument: overall level control, time and spectrum analysis. The two-channel option offers numerous other functions, such as orbit analysis for journal bearing machines and transfer function for the characterisation of mechanical resonances. Measurement data may be processed on a PC using the vib-Graph software.

Measurement organisation based on a 3-level tree structure Fast generation – using copy/paste functions at all levels.

Functions :

Instantaneous time spectrum

Power autospectrum

RMS spectrum

Cross-spectrum

Transfer function

Transmissibility

Coherence

Display

1, 2, 3, 4 traces

Linear or logarithmic amplitude, phase, real part, imaginary part

Orbit

Shock acquisition

Windowing

Averaging with validation

SPECS :

Touchscreen

Graphic colour touchscreen

Resolution: 800x480 pixels

Dimension: 154x92 mm (D7”)

Adjustable brightness

Can be used in direct sunlight

Icon functions

Touch keyboard

On touchscreen:

- 10 contextual function keys

- Functions are organised for single-hand measurement (left or right)

- Direct access to general functions: Home, Help, Setup, Screen copy, Picture, Bar code reader, Text note, Audio comment,Pyrometer, Stroboscope

- Full keyboard for text input. Several keyboards available: qwerty, azerty, Cyrillic,

Chinese

Acquisition

Synchronous on 4 channels trigger input 4-bits conversion

Sampling frequency:

- 102.4 kHz for each channel

- Up to 204.8 kHz on 1 channel

Antialiasing filter

Wireless acquisition with FALCON WLS triaxial

accelerometer

Digital signal processors

Real-time processing:

- 40 kHz on 4 channels

- Up to 80 kHz on 2 channels

Memory: 3.5 GB for measurements

Communication

USB 2 type B device (direct connection to PC)

USB 2 type A host (for USB stick)

Ethernet

Wi-Fi

Battery

Auto test and calibration function

High density Li-Ion type

Rechargeable without removing

Battery lifetime: 10 hours under intense use

Programmable automatic standby mode and switch-off

Analogue Inputs

Up to 4 programmable signal inputs (depending on instrument option):

- Frequency range: 0 - 40 kHz on 4 channels, 80 kHz on 1 channel

- Overload indicator in % with memorisation

- IEPE interface with real time integrity control, range 8V (power supply: 4 mA constant

current 23 VDC)

- Dynamic signal measurements (acceleration, vibration velocity, absolute displacement, relative displacement, electrical current, etc.)

- /- 10 VAC

- 0, -24 V for proximity probes (a -

24Vdc power supply is available

on each channel using cable ref

FLC1005000))

- Input impedance AC/DC: 100 kΩ

- Accuracy: /- 1%

- Dynamic range > 90dB

- Sensors without electronics with optional charge amplifier

- DC input: from -24 VDC to 24 VDC for measurements of position and process parameters

- AC coupling: 0.3 Hz

- Compatible with triaxial senso

Trigger input:

Range: /- 10 V, 0 to 24 V, 0 to – 24 V

Adjustable triggering parameters

Automatic setup function

For rotation speed measurement, synchronous analysis, balancing, order analysis.

Input impedance: 100 kΩ

5 Vdc power supply for tacho probe

-24 Vdc power supply for proximity probes driver using optional cable ref FLC1006000

Microphone input

Microphone input for audio inspection notes

ANALOGUE OUTPUTS

1 headphone output to listen sensor signal, recorded

signal or audio inspection notes

1 stroboscope output: TTL For each channel and trigger input:

-24 Vdc power supply for proximity probe

BUILT-IN PYROMETER WITH LASER-SIGHTING

Contactless temperature measurement:

- Range: 0 to 200°C

- Accuracy: /- 3°C for ambient temperature

ranging from 18°C to 28°C.

- Resolution: 0.5°C

- Repeatability: /- 1°C

- Field of view: 5° @ 50% ( target ≃ 4 cm @ 50 cm)

- Time response: 1 s

- Fixed emissivity: 95%

BUILT-IN STROBOSCOPE

Rotation speed measurement:

- Range: 30 to 15000 RPM

- Automatic setting to machine speed predefined in setup

- Adjustment:

-½, x2

-Fast

-Fine

- Flash duration : adjustable from 0.5 to 15°

- Can be used independently or to adjust rotation speed in a route or from a spectrumdisplay

Built-in camera

Resolution: 640 x 480

Autofocus

Distance: 20 cm to - Flash mode

Identification of measurement point

Built-in bar code reader

Reading distance: from 20 cm to 50 cm according to

code dimension

Bar code format: QRcode

Learning mode to avoid codes manual input

Mechanical/environment

Protection: IP65.

Case with shock protection rubber

Shock protection: 1.2 m drop (1m for EX version)

Standard compliance:

-Safety: IEC61010-1

-EMC: directive 2004-108-CE

Dimensions: 200 x 265 x 65 mm

Weight: 1.8 kg including battery and rubber protection

Operating temperature: -10°C to 55°C

Humidity: 95% no condensation

FALCON-EX, intrinsically safe version:

ATEX certification: EX II 3 G, Ex ic IIC T4 Gc, supplied

with certified accessories.

IECEX certification: Ex ic IIC T4 Gc

Note: shock protection: 1m drop. The protection screenaccessory cannot be used in dangerous area and is not supplied.

Remote access

FALCON can be set up so as to communicate with your network through its Ethernet or Wi-Fi interface and used as a remote station. You can then use the applications installed on your computer directly from FALCON (SUPERVISION, CMMS…).

Also you can check product : NEW Acoem Falcon Smart Data Collector Vibration Analyzers

Instant Machinery diagnostic & balancing

Like no other, the SMC ( Smart Machine Checker ) is a portable, machinery diagnostic tool that allows mechanics and maintenance technicians to check the health of any rotating machine, as needed, in a matter of minutes.

It requires no special training or certification and generates straightforward, simple machine diagnostic reports with both confidence and severity levels.

Features

AI-POWERED AUTOMATIC DIAGNOSTIC

Our built-in Accurex™ Artificial Intelligence can quickly provide a diagnosis of the issue, along with recommended solutions and actions, starting from the very first measurement

BUILT-IN CAMERA

For easy machine identification, sensor positioning, and report illustration

BUILT-IN STROBOSCOPE

The built-in stroboscope makes it easy to pinpoint the RPM which is crucial for securing an accurate diagnosis

THREE-AXIS WIRELESS SENSOR

The Acoem SMC wireless tri-axial sensor will take readings in the vertical, horizontal, and axial direction simultaneously making the measurement process fast and easy

BUILT-IN LASER PYROMETER

The Acoem SMC has a built-in laser pyrometer that makes it easy to take the temperature of your machine to verify your diagnosis

Smart Machine Checker: How it Works

Accurate machinery diagnostics in 3 simple steps

- Select the machine you want to diagnose from the device.

- Take readings at each of the automatically designated points.

- View the machine diagnostic report to learn what is wrong and what you need to fix.

The SMC is also available as EX system, Acoem SMC EX EX – ATEX Zone II 3 G Ex ic IIC T4Gc (ZONE II Industry where explosive atmosphere, consisting of a mixture of air and combustible material in the form of gases, smoke or fog, is likely to be formed sometimes during normal operation. Mines excluded.) It has the same performance and capabilities as the SMC.

Benefits

The Smart Machine Checker is designed to be used by machinery mechanics to give a clear and accurate automatic diagnosis of rotating equipment. Requires no vibration expertise or internet connection.

Intuitive interface

Right/Left hand operation

7-inch touch screen

Color coded results

Wireless Triaxial Sensor

Accurex machinery diagnostics

Built-in strobe light, pyrometer and camera

MS Word reporting

Accurex - Automatic machine diagnosis

Acoem SMC unique automatic machine diagnostic Accurex is built into the Acoem SMC. The innovative machine diagnostics feature provides unbeatable fast, relevant and reliable results for a wide range of machine problems such as unbalance, alignment errors, cavitation, structural resonances, bearing problems, and more. Acoem SMC machine diagnostic function differs from all other systems.

SPECIFICATIONS :

Touchscreen

Graphic colour touchscreen

Resolution: 800x480 pixels

Dimension: 154x92 mm (D7”)

Adjustable brightness

Can be used outdoors

Icon functions

Touch keyboard

On touchscreen:

- 10 contextual function keys

- Functions are organised for single-hand measurement (left or right)

- Direct access to general functions: Home, Help, Setup, Screen copy, Picture, Bar code reader, Text note, Audio comment, Pyrometer, Stroboscope

- Full keyboard for text input. Several keyboards available: qwerty, azerty, Chinese…

Acquisition

Synchronous on 4 channels trigger input

24-bits conversion

Sampling frequency: 51.2 kHz

Antialiasing filter

Wireless acquisition with WLS triaxial

accelerometer

Digital signal processors

Memory: 3.5 GB for measurements

Communication

USB 2 type B device (direct connection to PC)

USB 2 type A host (for USB stick)

Ethernet

Wi-Fi

Battery

Auto test and calibration function

High density Li-Ion type

Rechargeable without removing

Battery lifetime: 10 hours under intense use

Programmable automatic standby mode and

switch-off

Analogue Inputs

- Overload indicator in % with memorisation

- IEPE interface with real time integrity control, range 8V (power supply: 4 mA constant

current 23 VDC)

- Dynamic signal measurements (acceleration, vibration velocity) /- 10 VAC

- Input impedance AC/DC: 100 kΩ

- Accuracy: /- 1%

- DC input: from -24 VDC to 24 VDC for measurements of position and processparameters

- AC coupling: 0.3 Hz

- Compatible with triaxial sensor

Trigger input:

Range: /- 10 V, 0 to 24 V, 0 to – 24 V

Adjustable triggering parameters

Automatic setup function

For rotation speed measurement, synchronous

analysis, balancing, order analysis.

Input impedance: 100 kΩ

5 Vdc power supply for tacho probe

Included :

Display unit with full VGA 7″ color display unit with IP-65 rating

Built-in Strobe light

Built-in Camera

Built-in Pyrometer with laser targeting

Wireless Triaxial sensor

Carrying Case

Power supply to SMC

USB Charger for Sensor

Carrying case – IP-65, high impact ABS

Mounting Pads

Manual

Also you can check product : USED Acoem Hawk Oneprod HAPT2069C Vibration Analysis

EASY TO GET STARTED

- Easy to incorporate in your current maintenance practices

- Plug & Play

AUTOMATIC DIAGNOSIS IN THE FIELD

- No specialized vibration knowledge needed

- Instant results beside the machine

- Improved productivity of all repair actions

- If needed, easily get the advice of an ONEPROD expert

WIRELESS MEASUREMENT

- Personnel safety

- User comfort

- No measurement errors due to poor cable condition

FAST & RELIABLE BALANCING OPTION

- Step by step procedure

- Automatic trial-weight recommendation

- Automatic balancing grade assessment

- Automatic ISO standards comparison

SPECS :

Touchscreen

Graphic colour touchscreen

Resolution: 800x480 pixels

Dimension: 154x92 mm (D7”)

Adjustable brightness

Can be used outdoors

Icon functions

Touch keyboard

On touchscreen:

10 contextual function keys

Functions are organised for single-hand

measurement (left or right)

Direct access to general functions: Home, Help, Setup, Screen copy, Picture, Bar code

reader, Text note, Audio comment, Pyrometer, Stroboscope

Full keyboard for text input. Several

keyboards available: qwerty, azerty, Chinese…

Acquisition

Synchronous on 4 channels trigger input

24-bits conversion

Sampling frequency:

102.4 kHz for each channel

Up to 204.8 kHz on 1 channel

Antialiasing filter

Wireless acquisition with HAWK WLS triaxial

accelerometer

Digital signal processors

Real-time processing:

40 kHz on 4 channels

Up to 80 kHz on 2 channels

Memory: 3.5 GB for measurements

Communication

USB 2 type B device (direct connection to PC)

USB 2 type A host (for USB stick)

Ethernet

Wi-Fi

Battery

Auto test and calibration function

High density Li-Ion type

Rechargeable without removing

Battery lifetime: 10 hours under intense use

Programmable automatic standby mode and switch-off

Analogue Inputs

Up to 4 programmable signal inputs (depending on

instrument option):

Frequency range: 0 - 40 kHz on 4 channels,

80 kHz on 1 channel

Overload indicator in % with memorisation

IEPE interface with real time integrity control,

range 8V (power supply: 4 mA constant

current 23 VDC)

Dynamic signal measurements (acceleration,

vibration velocity, absolute displacement,

relative displacement, electrical current, etc.)

o /- 10 VAC

o 0, -24 V for proximity probes (a -

24Vdc power supply is available

on each channel)

Input impedance AC/DC: 100 kΩ

Accuracy: /- 1%

Sensors without electronics with optional

charge amplifier

DC input: from -24 VDC to 24 VDC for

measurements of position and process

parameters

AC coupling: 0.3 Hz

Compatible with triaxial sensor

Trigger input:

Range: /- 10 V, 0 to 24 V, 0 to – 24 V

Adjustable triggering parameters

Automatic setup function

For rotation speed measurement, synchronous analysis,

balancing, order analysis.

Input impedance: 100 kΩ

5 Vdc power supply for tacho probe

-24 Vdc power supply for proximity probes

Microphone input

Microphone input for audio inspection notes

ANALOGUE OUTPUTS

1 headphone output to listen sensor signal, recorded

signal or audio inspection notes

1 stroboscope output: TTL

For each channel and trigger input:

-24 Vdc power supply for proximity probe

BUILT-IN PYROMETER WITH LASER-SIGHTING

Contactless temperature measurement:

Range: 0 to 200°C

Accuracy: /- 3°C for ambient temperature

ranging from 18°C to 28°C.

Resolution: 0.5°C

Repeatability: /- 1°C

Field of view: 5° @ 50%

( target ≃ 4 cm @ 50 cm)

Time response: 1 s

Fixed emissivity: 95%

BUILT-IN STROBOSCOPE

Rotation speed measurement:

Range: 30 to 15000 RPM

Automatic setting to machine speed predefined in setup

Adjustment:

½, x2

Fast

Fine

Flash duration : adjustable from 0.5 to 15°

Can be used independently or to adjust rotation speed in a route or from a spectrum display

Built-in camera

Resolution: 640 x 480

Autofocus

Distance: 20 cm to

Flash mode

Identification of measurement point

Built-in bar code reader

Reading distance: from 20 cm to 50 cm according to code dimension

Bar code format: QRcode

Learning mode to avoid codes manual input

Mechanical/environment

Protection: IP65.

Case with shock protection rubber

Shock protection: 1.2 m drop (1m for EX version)

Standard compliance:

Safety: IEC61010-1

EMC: directive 2004-108-CE

Dimensions: 200 x 265 x 65 mm

Weight: 1.8 kg including battery and rubber protection

Operating temperature: -10°C to 55°C

Humidity: 95% no condensation

HAWK-EX, intrinsically safe version:

ATEX certification : EX II 3 G, EEx ic IIC T4 supplied with

certified accessories.

IECEX certification (pending)

Note: shock protection: 1m drop. The protection screen accessory cannot be used in dangerous area and is not

supplied.

Remote access

HAWK can be set up so as to communicate with your network through its Ethernet or Wi-Fi interface and used

as a remote station. You can then use the applications installed on your computer directly from HAWK (SUPERVISION, CMMS…).

Also you can check product : NEW Acoem RT-300 Shaft Alignment Tool and Condition Monitoring

- 1